A Value Analysis of Lean IPD: Lessons Learned in the Development of a Framework

- John Bienko

- Upali Nanda, PhD

- Bernita Beikmann

What is the Aim?

Challenge

Lean-IPD is increasingly practiced yet it is not clear how various stakeholders feel about it.

Aim

This presentation asks the following questions:

- What are the advantages and challenges of using lean thinking?

- What is the definition of “value”?

- What are the explicit benefits and costs that are currently reported/tracked

- What are the benefits and costs that are currently implicit (not measured/reported)?

- What is the Framework for benefit-cost (B/C) and/or Return On Investment (ROI) calculations?

- How can the benefits/costs related to design decision making be tracked in order to enable an ROI for both first costs and operational costs?

What We Did

Approach

This presentation showcases a case study from Akron Children’s Hospital in order to further an understanding of lean thinking. Lean thinking was incorporated into the project’s programming, design, and construction processes making it a useful setting for this research study. The research highlighted in this presentation explores the advantages and challenges of using lean thinking in the IPD process, offers a definition of “value” and quality metrics, provides a framework for cost/benefit assessment based on metrics currently tracked and considers and exploration of implicit costs and benefits.

Method

The research highlighted in this presentation adopted a multimethod data collection approach that consisted of the use of archival data via E-Builder, a site visit, interviews, focus groups and surveys. Lean processes adopted by the Akron Children’s Hospital project were captured, in part, through observations during a site visit to big room meetings.

What We Found

Results

This study was able to illustrate additional metrics, including safety, local participation, quality, energy efficiency, team performance, LEED and staff and family satisfaction that illustrate how the success of a project is determined by more than just its cost. Based on the evidence gathered, this research was also able to highlight that the idea of ‘learning’ emerged as the most consistent implicit benefit of Lean IPD amongst stakeholders, however this benefit is typically not tracked or invested in as a measure of success.

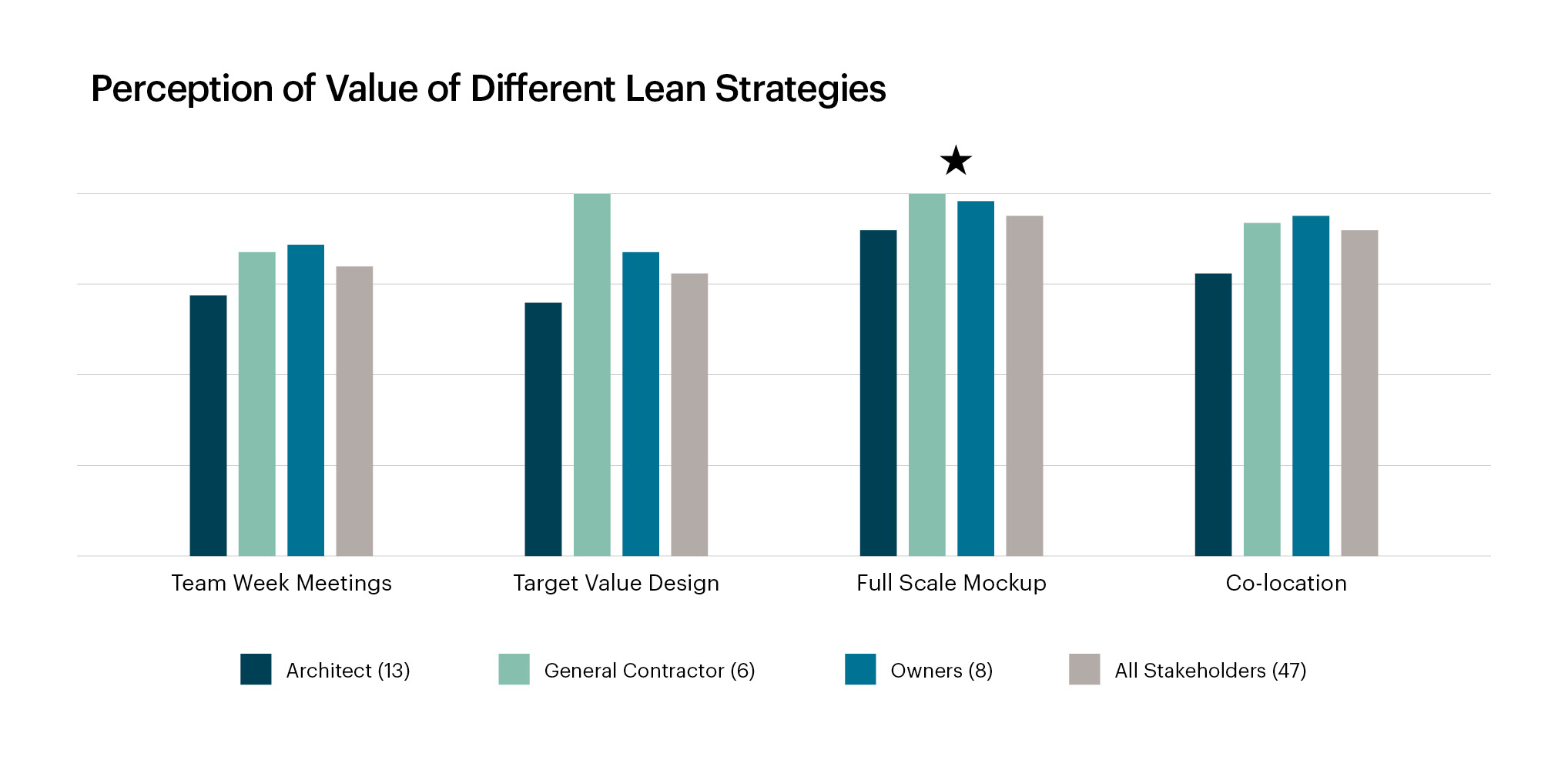

Additionally, in exploring different lean strategies, including TVD, big room meetings, co-location and full scale mock-ups, it was determined that a full scale cardboard mock-up workshop was the most successful strategy.

Moreover, this research found that although the assumption in an IPD project is that all stakeholders have equal voice, the perceptions regarding this may vary. Survey results indicated that the owner is perceived as having the largest influence in the process, followed closely by the General Contractor. Therefore, it was determined that the perception of value differs between stakeholders and is dependent on who the stakeholder perceives as the ultimate customer.

Finally, this presentation highlighted that the notion of ‘value’ can mean many different things. Current evaluation of ‘value’ is still primarily based on first cost and does not take operational cost savings into consideration.

Deliverable

This research illustrated that the use of lean strategies and an IPD process was deemed successful, especially with respect to controlling cost and schedule and improving learning. This presentation includes a preliminary framework that can aid in understanding the benefits of lean thinking as understood from the metrics of time, cost, safety, quality, morale, and learning.

This research illustrated that the use of lean strategies and an IPD process was deemed successful, especially with respect to controlling cost and schedule and improving learning.

What the Findings Mean

Application

By adopting a Lean-IPD-TVD approach, a higher quality project can be delivered at a lower cost by utilizing early and continuous stakeholder input and engagement.

Future

This presentation outlines various success metrics that can contribute towards an improved understanding of lean thinking, however future research is needed in order to translate these success metrics into an ROI. This presentation suggests three additional components that are needed in order to achieve this goal; these include: a baseline of benefits and costs in comparable traditional Design Bid Build projects to allow a benchmark for comparison, a more thorough documentation of incremental (additional) costs associated with the decision-making process involved in a Lean-IPD project, and an assessment of the long-term/occupancy implications of design decisions.

Acknowledgements

Team Members:

Di Ai

John Bienko

Upali Nanda

Zofia Rybkowski

Funding:

AIA Academy of Architecture for Health Foundation

HKS

Boldt